Lead-Lined Plywood (ACX FRT) – Radiation Shielding Backer Panels

Specifications & Key Information

- Product Type: Lead-Lined ACX FRT Fire-Retardant Plywood

- Standard Plywood Thickness: 3/4" (1/2" optional)

- Lead Thickness Range: 1/8" up to 1" lead thickness

- Standard Panel Size: 16" W x 84" H lead on 16" W x 96" H plywood

- Optional Full-Height Panel: 16" W x 96" H lead on 16" W x 96" H plywood

- Optional Widths (Custom Quote): 12", 24", and custom sizes available

- Accessories Included: (1) 2" wide vertical lead batten strip per sheet + 50 lead discs for fastener coverage

- Fabrication Time: Approximately 3 Business Days

- Lead Purity: 99.9% Pure Lead Sheet

- Fire Rating: ACX FRT (Fire-Retardant Treated)

Compliance & Standards

- ASTM E84 – Grade C

- ASTM 3201

- ASTM D5516

- ASTM D6305

- AWPA U1 & T1

- International Building Code (IBC) Section 2303.2

- MIL-L-1914E

- Federal Specification QQ-L-201-F, Grade C

- ASTM B749-03

Heavy-Duty Radiation Shielding for High Lead Thickness Applications

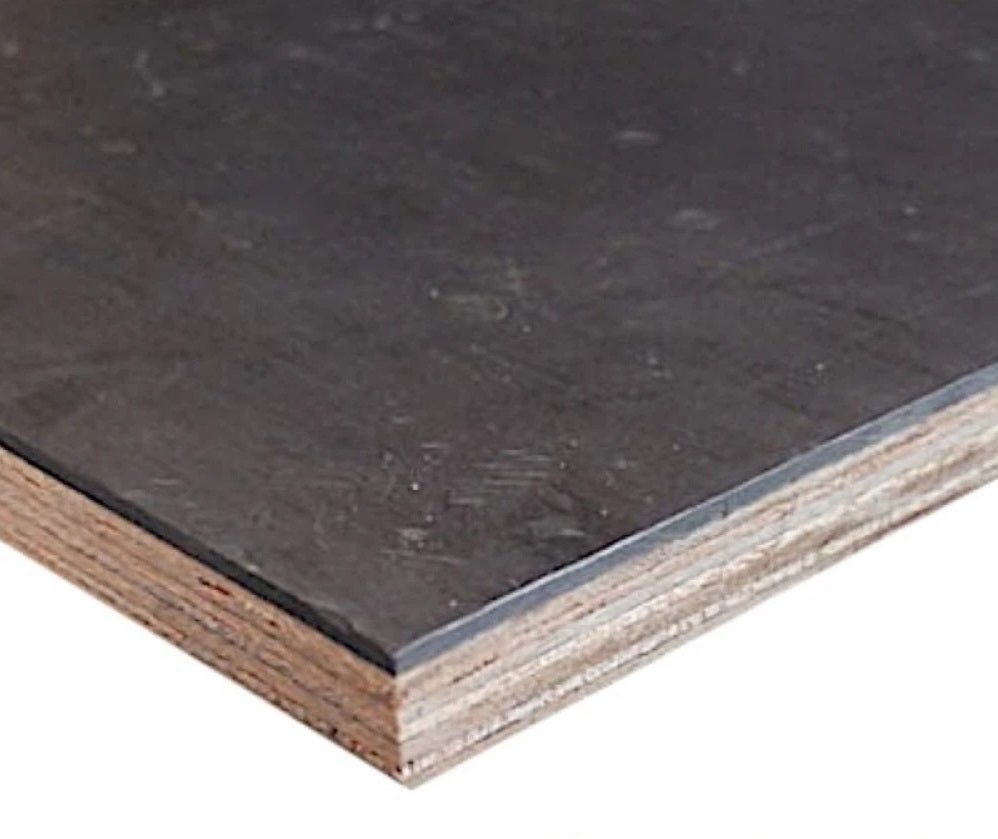

Lead Glass Pro Lead-Lined Plywood panels are engineered specifically for radiation shielding projects requiring thicker lead sheets where standard drywall or sheetrock cannot safely support the weight. When lead thickness exceeds 1/8", the structural integrity of traditional gypsum-based systems becomes insufficient — making lead-backed plywood the preferred and compliant solution for medical imaging and radiation environments.

These panels combine 99.9% pure lead with fire-retardant ACX plywood to deliver both structural strength and reliable radiation attenuation in demanding healthcare and construction environments.

Designed for Medical Imaging & Shielding Construction

Lead-lined plywood is commonly specified in X-ray rooms, CT suites, PET rooms, interventional radiology labs, and other shielded environments where higher lead equivalency is required. The plywood backing provides the necessary load-bearing support for thick lead while maintaining code compliance and installation durability.

In single-story buildings, lead shielding is typically only required up to 84" in height, which is why our standard configuration includes 84" lead coverage on a 96" plywood panel. Full-height 96" lead coverage is available when specified by a physicist or shielding report.

Standard Sizes & Custom Fabrication

Our most common configuration is 16" wide panels designed to align with standard stud spacing, allowing for efficient installation and minimal field modification. Each sheet includes a vertical lead batten strip to maintain shielding continuity at panel joints and lead discs to properly cover fastener penetrations.

Custom widths including 12", 24", and fully custom dimensions are available to meet project-specific shielding layouts, architectural drawings, and physicist specifications.

Built for Code Compliance & Inspection Approval

Every Lead Glass Pro lead-lined plywood panel is manufactured using high-purity lead that meets federal and ASTM standards for radiation shielding. The ACX FRT plywood core complies with fire-retardant treatment requirements and applicable building codes, making it suitable for healthcare construction, hospital renovations, and new imaging facility builds.

What’s Included With Each Sheet

- Precision-bonded lead sheet laminated to ACX FRT plywood

- One 2-inch wide vertical lead batten strip (for joint shielding continuity)

- 50 lead discs for screw head radiation coverage

- Clearly labeled lead equivalency for inspection and documentation

Why Choose Lead Glass Pro Lead-Lined Plywood?

- Designed specifically for thick lead shielding applications

- Fast 3-day fabrication turnaround

- Fire-retardant ACX plywood core

- High-purity 99.9% lead for reliable attenuation

- Standard and fully custom sizes available

- Trusted in hospitals, imaging centers, and radiation facilities nationwide

Need help selecting the correct lead thickness or panel configuration? Our team can review your shielding report or plans and recommend a compliant solution for your project.