Lead Lined Drywall Specifications

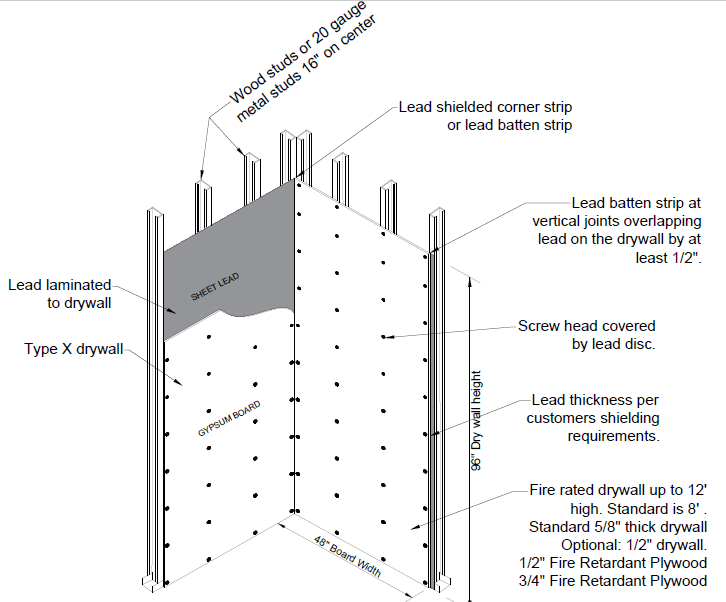

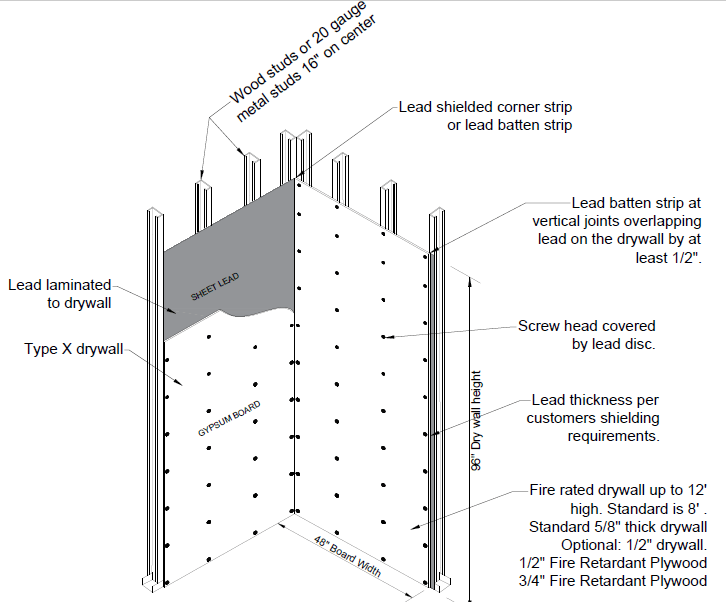

- Standard Sizing: 4ft x 7ft lead on 4ft x 8ft board

- Standard Drywall Thickness: ⅝” fire-rated sheetrock gypsum wall boards (½” non-rated is available upon request)

- Accessories: Includes one 2" wide vertical batten strip per sheet for joints and 50 lead discs per sheet that can be placed over the screw heads

- Compliance: Drywall boards are fire rated and meet ASTM C1396 standard. Lead sheets meet or exceed federal specifications QQ-L-201 F, Grade C and ASTM B749-03.

- Fabrication Time: Typically ships within 2 days. Note: It is imperative that you have a forklift on-site for offloading your lead lined sheetrock materials.

Customization Options

- Custom Lead Height: Lead Height can be up to 12’. Board Height can be up to 12’. Standard lead height is 7’0” which is the federal minimum height requirement for a single story building.

- Custom Lead Thickness: We have 11 standard lead thicknesses for lead lined drywall ranging from 1/64" (1#) to 1/4" (16#)

- Higher Lead Equivalencies: We can fabricate lead lined plywood for heavier lead thicknesses from 1/8" (8#) to 2" (120#)

- Optional Materials: Choose from mold-resistant or abuse-resistant drywall

High-Quality Lead Lined Walls

Shield employees, visitors, patients, and equipment from the harmful impacts of radiation with lead lined drywall. Durable and reliable, our lead lined walls offer high levels of protection absorbing dangerous X-ray, gamma, alpha, and beta photon radiation.

Benefit from superior engineering, high-grade lead sheets, and drywall made to your custom specifications today. We use the highest purity lead available at 99.9% for optimal safety. Uniform density ensures consistent protection throughout.

Use lead lined drywall in the construction of rooms that will contain X-Ray machines, CT scanners, PET scanners and any other space where radiation will be present. Lead lined drywall installation is vital in medical clinics, dental clinics, hospitals, veterinary surgeries, laboratories, and more.

Lead Lined Drywall Installation Considerations

- Turnaround Time: The typical fabrication time for lead lined drywall is 2 days. Fabrication begins when you place an order so your order cannot be changed or cancelled thereafter.

- Safety: You must use the appropriate safety gear and a forklift on-site to offload lead lined walls. All lead equivalency calculations must be determined by a radiation physicist or local official.

- Lead Lined Drywall Installation:

- First, the provided lead batten strip is required at every vertical joint to provide the correct radiation shielding overlap, as required by the NCRP (National Council on Radiation Protection).

- Next the lead lined sheetrock is installed similar to standard sheetrock. However, it cannot be installed horizontally, it must be installed vertically.

- Last, the screw heads must be covered with the provided lead discs. This only applies to lead thicknesses over 1/16”. For 1/16” and thinner lead, the NCRP allows for no additional lead shielding for the screws because the screw itself attenuates the radiation.

- In the U.S., if there is no occupancy above the room, the lead shielding is only required to extend to 7’ AFF (Above Finished Floor) regardless of the height of the walls and is not required on the ceiling. This is because radiation is linear and does not change direction so it will naturally continue upwards and eventually become insignificant. Similarly, if there is no occupancy below, lead shielding is not required on the floor as it will be shielded by the ground.

- Order Verification: Please inspect your order carefully in the presence of the delivery driver and report any damages or complaints on your delivery receipt. Once the receipt is signed you will not be able to make damage claims.

Medically and Federally Approved Lead Lined Sheetrock

Lead Glass Pro’s lead backed drywall is approved for the medical x-ray, gamma, alpha, and beta photon shielding. It is, however, not intended for thermal neutron or fast neutron shielding. Customers should note that lead does not shield against Magnetic Resonance Imaging (MRI), electro-magnetism or radio-frequency, ultrasound, laser or any non-ionizing types of radiation. Our lead backed drywall also meets Federal Specification QQ-L-201F, ASTM B749, ASTM C 1396 requirements, and all applicable current NCRP and ICRP (International Commission on Radiological Protection) lead shielding criteria, standards, and physical quality requirements.

FAQs

Are lead lined walls safe?

Lead lined walls are safe when properly installed by professionals because the lead faces the interior wall cavity, so it’s not exposed. Lead itself, however, is toxic if ingested or inhaled so it is essential that the material is properly installed. When handling lead lined drywall, it’s essential to wear protective gear, including gloves, a respirator, and safety goggles.

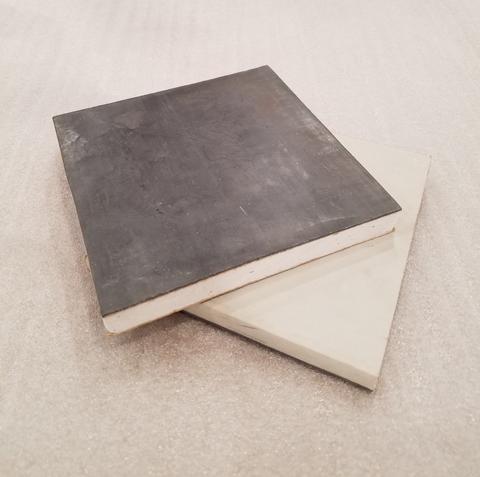

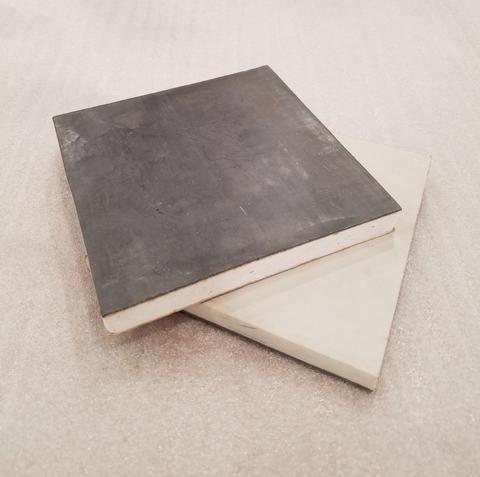

How is lead-lined drywall manufactured?

Lead lined drywall is created by bonding a sheet of lead to standard gypsum drywall. The lead sheet varies in thickness depending on your radiation protection needs and is laminated to the back of the drywall panel. This composite material is then installed in radiation-shielded spaces.

How much radiation protection does lead provide?

Lead is highly effective at blocking radiation. The amount of protection you require depends on the type and energy of the radiation. Radiation shielding must be designed by a qualified expert such as a radiation physicist, medical health physicist, or county health officer who is competent in designing radiation shielding for medical x-ray imaging facilities. The qualified expert must be certified by the American Board of Radiology, American Board of Health Physics, or the Canadian College of Physicists in Medicine to ensure the required degree of protection is achieved. The qualified expert should always be consulted during the early planning stages as the shielding requirements may affect the choice of location of radiation facilities and the type of building construction. They should be provided with all pertinent information regarding the proposed radiation equipment and its use, type of building construction, and occupancy of nearby areas so that they can determine the necessary Lead Glass Pro lead lined drywall and add-ons for your specific situation.

NOTE:

- Customer must verify lead equivalency meets the shielding requirements of the room

- Payment will be required to begin fabrication.

- Once fabrication begins, no cancellations or changes may take place

- By placing an order and paying you accept and have verified sizes, quantities, lead equivalency, and accept the terms for shipping / receiving and returns / replacement

- All products must be inspected upon delivery in the presence of the delivery driver. Once the product is received and the delivery receipt is signed, no claims for damage will be entertained. If there is damage, note it on the delivery receipt and contact us immediately.

- All radiation shielding calculations must be determined by a radiation physicist.

- A forklift is required for offloading

- Our products can only ship to a commercial address. We cannot ship to residential addresses.