Lead Backed Drywall for X-Ray Rooms

We can provide it on either 1/2" non-rated or 5/8" fire rated sheetrock gypsum wall board. Our board meets ASTM C1396, and the pure sheet lead we use meets Federal Specification QQ-L-201 F, Grade C and ASTM B749-03, Type L51121 factory laminated under pressure to the back side of the drywall. It is custom manufactured to customer specifications and is typically available in 2 days.

- Standard size is 4ft x 7ft lead on 8ft board.

- Typical fabrication time is 2 days.

- Available in 1/2" and 5/8” drywall (5/8" standard)

- Includes one 2" vertical batten strip per sheet for joints and 50 lead discs per sheet that can be placed over the screw heads

- We have 11 standard lead thicknesses for lead lined drywall ranging from 1/64" (1#) to 1/4" (16#)

- We can fabricate lead lined plywood for heavier lead thicknesses from 1/8" (8#) to 2" (120#)

- Lead height is the federal minimum of 7'0"

- Lead can optionally be up to 12'0" high (standard is 7' lead on 8' board)

- Optional Mold Resistant or Abuse Resistant wall board

Select your lead thickness and quantity to purchase.

A custom quote request can be sent to sales@leadglasspro.com if you do not see your requirements listed here

You must have a forklift on-site for offloading this material.

Radiation Shielding with Lead Backed Drywall

Lead lined drywall is the preferred choice when constructing a room that requires shielding from radiation. Lead backed drywall, also known as lead lined sheetrock, lead lined wall board or lead backed gypsum, offers effective protection against radiation. It is commonly used in the construction of x-ray rooms and other medical facilities where radiation safety is a concern. Radiation shielding with lead backed drywall is an important part of keeping both patients and staff safe from the harmful effects of radiation exposure.

Request a custom quote from Lead Glass Pro now!

Why Protecting Against Radiation with Lead Backed Drywall is Essential

Radiation exposure can have harmful effects on the human body, including DNA damage and skin burns. Lead is an effective shielding material because it absorbs and scatters radiation. When lead is used in drywall, it forms a barrier that helps to protect against harmful radiation exposure. In addition to lead windows and lead lined frames, lead backed drywall must be used in radiation producing rooms such as CT Scanners, General X-Ray Rooms, Fluoroscopy, PET Scanner Rooms and anywhere else radiation imaging or therapy is taking place. It is, however, important to note that lead backed drywall is not to be used in MRI rooms.

Why Use Lead Backed Gypsum / Lead Backed Drywall?

Lead backed drywall is used across a wide array of industries due to its safety, price, and efficiency. Lead backed gypsum / drywall is also extremely versatile, and can be customized in size and shape in the field, which means that no pre-cutting is required. In addition to its superior lead shielding properties, lead backed drywall is:

- Non-flammable

- Resistant to mold and mildew

- Easy to install

- Durable and long lasting

- Reduced noise transmission

- Eco-friendly

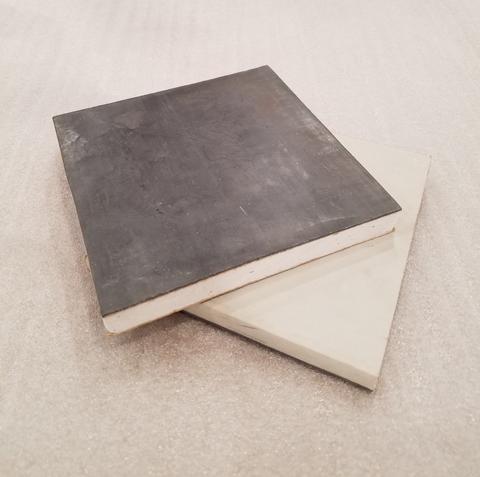

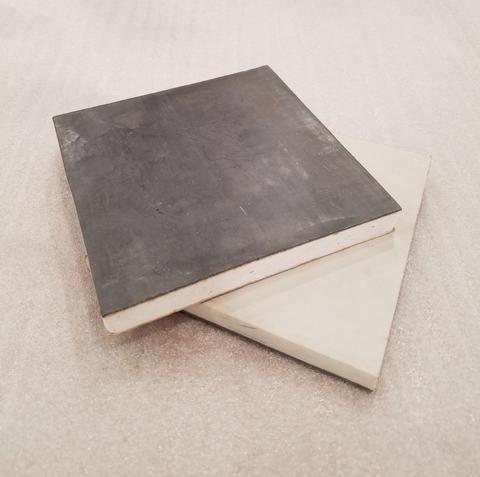

How is Lead Backed Drywall Made?

Lead backed drywall or lead lined sheetrock consists of a sheet of drywall with a lead backing. It is a laminated product consisting of UL Fire rated drywall and pure lead sheet metal. The lead backing provides the majority of the radiation protection, while the drywall itself helps to support the lead and provides a surface for it to be applied to. The lead provides an effective barrier against x-rays and other types of ionizing radiation. Lead backed drywall / lead lined sheetrock is available in different thicknesses, depending on the level of radiation protection that is required. Lead shielding requirements can only be determined by a licensed radiation physicist or your county health department.

- Lead Glass Pro offers the highest purity lead drywall available for the most efficient medical radiation shielding, 99.9% pure

- Lead Glass Pro ensures that its materials are uniformly dense and have a high-quality composition, which provides a dependable shielding value.

- Lead Glass Pro’s lead drywall is approved for the medical x-ray, gamma, alpha, and beta photon shielding only. And is NOT for thermal neutron or fast neutron shielding. Lead does NOT shield against Magnetic Resonance Imaging (MRI), electro-magnetism or radio-frequency, ultrasound, laser or any non-ionizing types of radiation.

- Lead Glass Pro x-ray protective lead drywall meets Federal Specification QQ-L-201F, ASTM B749, ASTM C 1396 requirements and all applicable current NCRP and ICRP lead shielding criteria and standards and physical quality requirements.

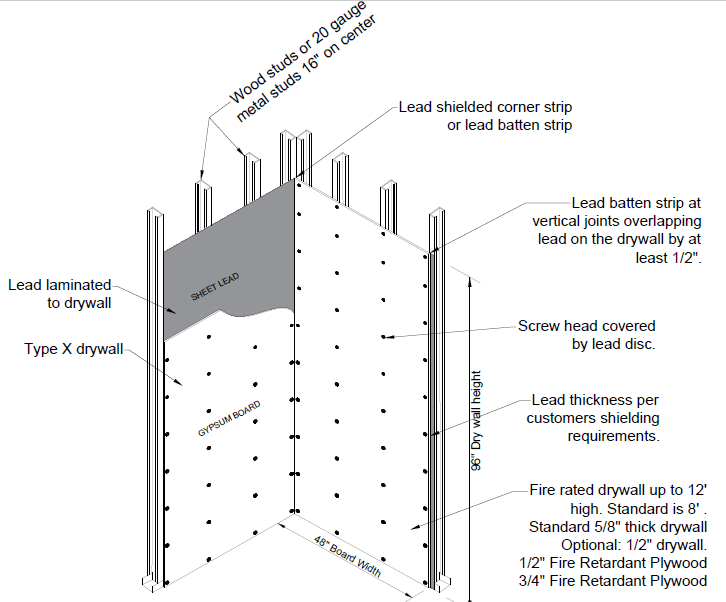

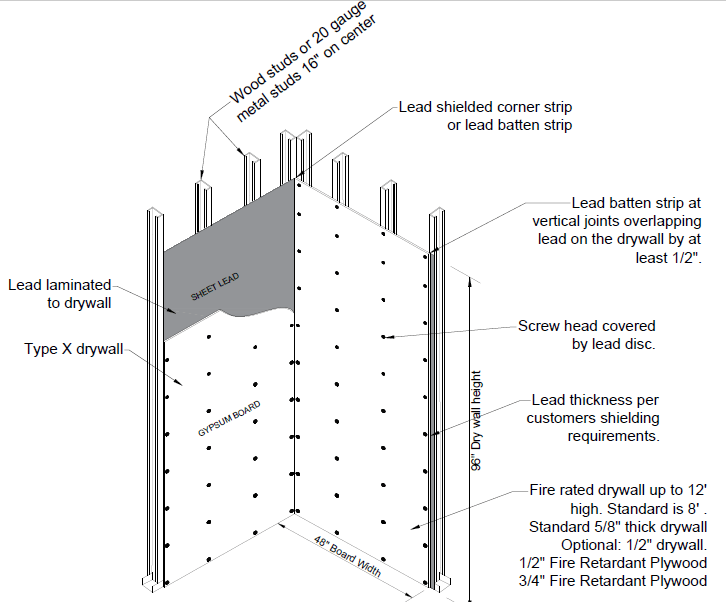

Lead Backed Drywall Installation: Explained

Lead lined sheetrock cannot be installed horizontally. Rather, it is installed vertically. A vertical lead batten strip is required at every joint to provide the correct radiation shielding overlap, as required by the NCRP (National Council on Radiation Protection). The screw layout is 8” on center for the vertical edge, and 12” on center for the intermediate studs. Screw heads must be covered by lead discs for any lead thickness that is over 1/16”. For 1/16” and thinner lead, the NCRP allows for no additional lead shielding for the screws because the screw itself attenuates the radiation.

Have a question about the installation process? Contact our team of experts to learn more!

How to Choose Lead Lined Sheetrock

The Thickness of Your Lead Backed Drywall

The thickness of lead lined sheetrock that is required will depend on the level of radiation that is being shielded against. Lead shielding requirements can only be determined by a licensed radiation physicist or your county health department.

Your Lead Backed Drywall's Size

Lead lined sheetrock is available in a variety of standard sizes, or it can be custom cut to size. The lead backing can also be applied over drywall that has already been installed, which means that lead lined sheetrock can be retrofitted into existing buildings.

The Cost of Your Lead Backed Drywall

The cost of lead lined sheetrock will vary depending on the thickness of lead that is required and the size of the sheets. However, lead lined sheetrock is a long-term investment and a premium quality product should last for many years.

Lead is Eco-friendly

In today's world, sustainability is an important consideration for many customers. Lead is a sustainable material that can be re-melted, recycled and reused indefinitely. In fact, much of the lead used in today's lead products is recycled from previous generations of products, making it a sustainable choice for shielding against radiation.

Lead Glass Pro's Lead Backed Drywall

Lead Glass Pro offers the highest purity lead drywall available for the most efficient medical radiation shielding. The lead we use is the purest available at 99.9% pure. This means that our lead backed gypsum provides the highest level of radiation protection possible. Too often, other manufacturers have used Grade B (95% pure) which is not approved for radiation shielding in the U.S. and is only intended for roofing or sound proofing. Lead Glass Pro's customers can rest assured that our materials are uniformly dense and have a high-quality composition, which provides a dependable shielding value.

Lead Glass Pro's Lead Backed Drywall Height and Thickness Options

Lead Glass Pro offers 11 standard lead thicknesses for our lead lined sheetrock, ranging from 1/64” to 2” thick. For heavier lead shielding thicknesses, we do offer custom quotes on request at sales@leadglasspro.com. In the case that you do require heavier lead thicknesses from 1/8" (8#) to 2" (120#), we fabricate lead lined plywood to your specifications. Our standard size for lead backed drywall is 4ft x 7ft lead on an 8ft board but we can provide either 1/2" non-rated or 5/8" fire rated sheetrock gypsum wall board. The federal minimum for lead height is 7' lead. Alternatively, we can provide custom lead heights up to 12'0" high. We also offer optional Mold Resistant or Abuse Resistant wall board to ensure the longevity of your investment.

Note: All lead backed drywall orders with Lead Glass Pro include one 2" vertical batten strip per sheet for joints, and 50 lead discs per sheet that can be placed over the screw heads at no additional cost. Lead corners are optional add-ons. We are committed to cost-efficiency and are continually making a concerted effort to reduce costs for our customers while upholding exceptional standards of quality.

Lead Glass Pro's Incomparable Lead Lined Sheetrock Fabrication Time

Lead Glass Pro has built a reputation in the industry for speed and efficiency. 99% of our lead backed drywall is shipped within 2 days of order placement. The transit time is only typically 1 to 4 days. That means that most Lead Glass Pro customers have their products, from start to finish, at their doorstep in a week. Other companies are known to take 5 or more weeks before an order is filled and delivered. We understand that time is of the essence when it comes to health and safety, which is why we pride ourselves on being able to provide a rapid turnaround without compromising on quality.

Note: It is imperative that you have a forklift on-site for offloading your lead lined sheetrock materials.

Medically and Federally Approved Lead Lined Sheetrock

Lead Glass Pro’s lead backed drywall is approved for the medical x-ray, gamma, alpha, and beta photon shielding. It is, however, not intended for thermal neutron or fast neutron shielding. Customers should note that lead does not shield against Magnetic Resonance Imaging (MRI), electro-magnetism or radio-frequency, ultrasound, laser or any non-ionizing types of radiation. Our lead backed drywall also meets Federal Specification QQ-L-201F, ASTM B749, ASTM C 1396 requirements, and all applicable current NCRP and ICRP (International Commission on Radiological Protection) lead shielding criteria, standards, and physical quality requirements.

Lead Glass Pro Lead Backed Drywall Add-ons and Options

Lead Glass Pro also offers a number of other options and add-ons for our lead lined sheetrock so that you can tailor the product to your specific needs and requirements. These include:

- 5/8” Fire Rated Drywall or 1/2” Non-Rated Drywall

- Mold Resistant or Abuse Resistant Board

- Lead Backed Plywood is available for thick lead applications

- Lead corners, additional lead batten strips, and additional lead discs

- Cut to size drywall and plywood for easy installation

- Board sizes up to 12’ are available with no extra fabrication time

- Lead corners for vertical corner joints

Important Considerations Before Ordering Your Lead Backed Drywall

We strive to make the ordering process for lead lined sheetrock as simple and straightforward as possible. However, there are a few key considerations that customers should take into account before placing your lead backed gypsum order in order to avoid any potential delays or issues.

Your sheet lead backing must be equal to or greater in value as the lead in the wall partition where penetration occurs.

It may be necessary to submit the final shielding drawings and specifications to pertinent regulatory agencies for review prior to construction.

Consulting with a Qualified Expert for Your Lead Backed Drywall

Radiation shielding must be designed by a qualified expert such as a radiation physicist, medical health physicist, or county health officer who is competent in designing radiation shielding for medical x-ray imaging facilities. The qualified expert must be certified by the American Board of Radiology, American Board of Health Physics, or the Canadian College of Physicists in Medicine to ensure the required degree of protection is achieved. The qualified expert should always be consulted during the early planning stages as the shielding requirements may affect the choice of location of radiation facilities and the type of building construction. They should be provided with all pertinent information regarding the proposed radiation equipment and its use, type of building construction, and occupancy of nearby areas so that they can determine the necessary Lead Glass Pro lead lined drywall and add-ons for your specific situation.

Contact Us Today!

For more information about our lead lined sheetrock and how we can help you create a safe x-ray room, contact us today. Our team of specialists would be happy to answer any questions you may have and provide a custom quote for your lead backed drywall.

- Customer must verify lead equivalency meets the shielding requirements of the room

- Payment will be required to begin fabrication.

- Once fabrication begins, no cancellations or changes may take place

- By placing an order and paying you accept and have verified sizes, quantities, lead equivalency, and accept the terms for shipping / receiving and returns / replacement

- All products must be inspected upon delivery in the presence of the delivery driver. Once the product is received and the delivery receipt is signed, no claims for damage will be entertained. If there is damage, note it on the delivery receipt and contact us immediately.

- All radiation shielding calculations must be determined by a radiation physicist.

- A forklift is required for offloading

- Our products can only ship to a commercial address. We cannot ship to residential addresses.